Experiences with an insulated slab

- Scott

- May 23, 2020

- 3 min read

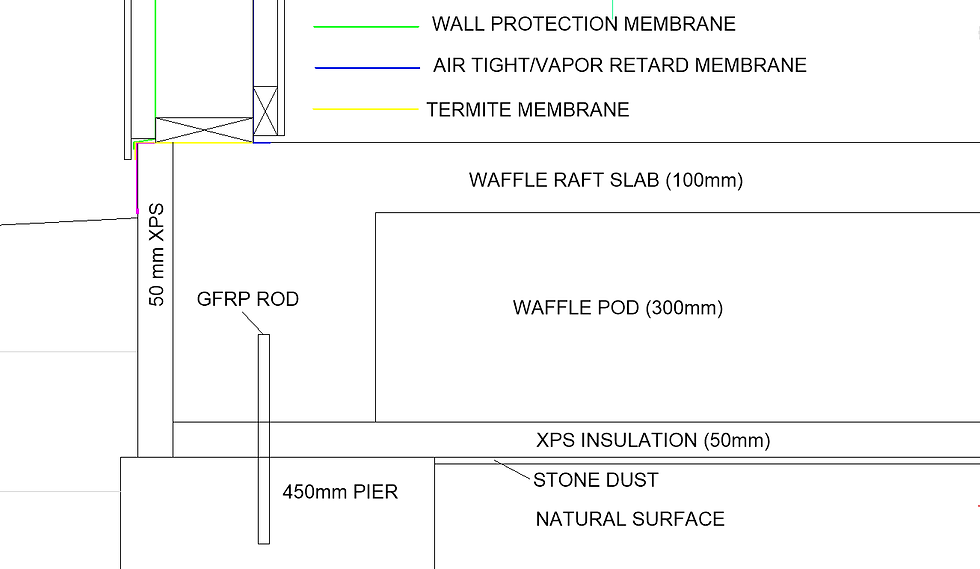

In our last blog, I mentioned that we are fully insulating the slab from the ground. In our Passive House Planning Package (PHPP) analysis, Luc specified a 50 mm extruded polystyrene (XPS) insulation layer under the entire slab and up the slab edge.

While some might choose to add the XPS to the slab edge after the pour, I figured it was easier to place all the insulation before hand using the formwork as support. This mostly went to plan but there were some learnings that came out that I’ll explain with the following photo’s.

1. All our piers were poured 5 to 10 mm above the leveled natural surface by placing a steel pin in the ground and then leveling off that during placement. This worked well and all pads were within 5mm of each other.

2. All the V-Rods were placed using a template set-off stringlines so that the concreters could locate reinforcing rods & trench mesh consistently on the one side of the rods.

3. A thin layer of stone dust was spread over the footprint to remove the remaining surface variability, matching the height of the pier pads so that the XPS would be fully supported. Much of the leveling had to be done by hand with a rake as it was difficult to get the surface finish right with the dingo that we used to haul the stone dust in. We lost one V-Rod when the dingo backed over it - fibreglass does not flex so the shattered remains were drilled out and a spare rod anchored in place using chemset.

4. The XPS insulation board we used (DCT GA300) has a tongue or groove edge to all four sides. This introduced a few challenges around the edges and meant oversizing holes for penetrations but on the whole it worked well. It didn’t need taping and I still think that there is less likelihood for the joins to compromise the insulation layer.

We started with installing the edge boards on the north and west sides then progressively installed the base boards before finishing off with the edge boards to the south and east. All corner joins were sealed with a flexible sealant and the inevitable gaps around penetrations were filled with a low expansion foam adhesive. Our only challenge was securing the edge boards – while we had planned to use a double sided tape, it would not stick to the previously-oiled formwork and the formwork’s vertical profile was not always straight anyway. Fortunately I also had rolls of gaffer tape and so plan B became a strip of gaffer tape over the XPS and under the back lip of the C-section to keep it in place. We set the top of the XPS edge board up 5mm above the concreter’s forms and levelled it with the laser on packers under the bottom edge. This worked well on the piers but I noticed foot traffic could push the packers into the stone dust in other areas.

5. Our only moment of concern came as the formwork started getting stripped. Formwork is usually stripped the same day and we noticed that some edge insulation panels popped off the slab as the formwork was removed. We had generously scored the inside face of each XPS edge panel thinking it would allow the concrete to grip into it but apparently some of those panels were under enough pressure that this was not sufficient to hold them in place. Maybe leaving the formwork in place for an extra day or so may have helped, or possibly we should have used some plastic screws sitting proud of the surface (into the concrete) as well as the surface scoring but I think some panels – particularly at corners, were under a lot of pressure and were going to spring regardless. Our remedy was to hold it in place with steel pegs before getting SimDig in to place some of our piles of fill against the bottom of the panels and then to tape the top of the panel onto the slab using a wider version of the “this-will-stick-to-anything” Pro-Clima Extora tape that we are intending to seal membranes with in latter stages. It did the job perfectly and will keep the XPS in place until the frame and cladding locks everything together.

I need to give a big vote of thanks to Serge and Donny and all their team at Gallace & De Rose – it must be a leap of faith when booking concrete and pump trucks that rely on an owner builder getting their part done on time but with their flexibility and teamwork (I rolled out their plastic as I installed the XPS, in return they helped with sealing joins and checking levels) we had it all in place in good time. And also to Dean for jumping in to provide the extra labour needed when I was short handed.

Comments